A cikin masana'antun masana'antu na lantarki, injin daɗaɗɗen tawada da na'urorin bushewa sune mahimman hanyoyin haɗin gwiwa a cikin samarwa na hukumar PCB.Suna taka muhimmiyar rawa wajen tabbatar da ingancin allon PCB da inganta ingantaccen samarwa.Tunatar da masana'antun hukumar PCB cewa kayan aikin kowane masana'anta suna da fifiko da halaye daban-daban.Idan daidaitawar ba ta da kyau, yana iya haifar da illa.Bayan haka, Xin Jinhui zai yi nazarin muku sirrin daidaita na'urar toshe tawada ta PCB da tanderun rami, da kuma yadda za a taimaka wa masana'antun PCB su sami ninka ingantaccen tsari.

PCB kewayawa tawada tawada wani muhimmin mataki ne a cikin aikin bugu.Manufarsa ita ce tabbatar da hatimin ramukan don samar da inuwa mai kyau da kwanciyar hankali.Bushewar rami muhimmin tsari ne bisa wannan.Yana ƙarfafa tawada ta hanyar yin burodi mai zafi don ƙara haɓaka hatimin ramukan.

A lokacin aikin busar da tanda na rami, ramukan toshe tawada na PCB na iya hana danshi shiga yadda ya kamata, ta haka ne ke kare hukumar kewayawa daga lalacewar danshi.A lokaci guda kuma, kyakkyawan hatimin ramin toshe tawada kuma yana tabbatar da kwanciyar hankali a cikin ramin, yana sa tsarin bushewa ya zama daidai da inganci.Don haka, haɗin gwiwa tsakanin toshe tawada da bushewar rami ana iya cewa yana da alaƙa kuma ba za a iya raba su ba.

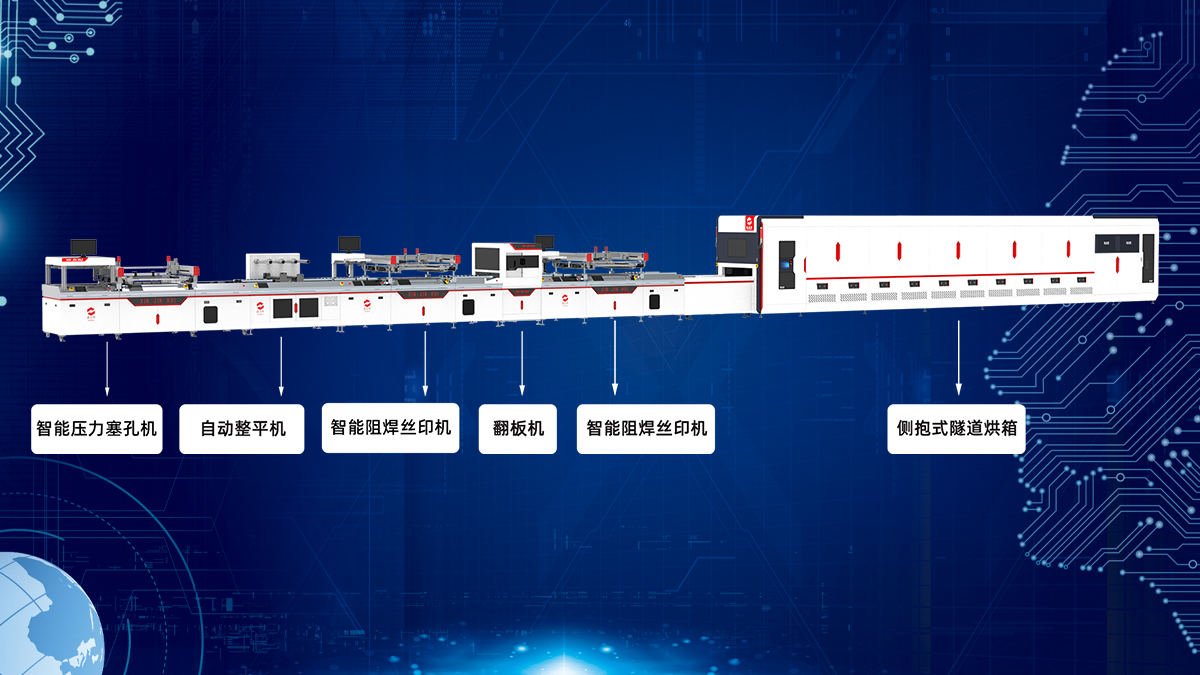

Don ƙara haɓaka haɓakar samarwa da inganci, yawancin kamfanonin masana'antu sun fara gabatar da fasaha ta atomatik don canzawa.Misali, layukan samarwa masu sarrafa kansa na iya kammala ayyuka ta atomatik kamar PCB tawada toshe da bushewa, rage sa hannun hannu da haɓaka ingantaccen samarwa.A lokaci guda kuma, tsarin kula da hankali na iya sa ido kan tsarin samarwa a ainihin lokacin, sarrafa kayan aiki daidai, rage yawan amfani da makamashi, da inganta ingantaccen amfani da makamashi.

Zaɓin kayan aiki masu inganci shima yana da mahimmanci.Misali, yin amfani da kayan bushewa masu inganci da tsarin sarrafa hankali na iya rage yawan kuzari.A lokaci guda, ta hanyar tsarin sarrafawa na hankali, haɗin kai tsakanin kayan aiki yana samuwa don ƙara inganta ingantaccen amfani da makamashi.Misali, ana haɗa kayan bushewa da kayan sanyaya tare don daidaita lokacin bushewa ta atomatik da lokacin sanyaya gwargwadon yanayin zafi, don haka adana kuzari.

Na'urorin toshe tawada na PCB na al'ada galibi basu da isassun ramukan toshewa saboda matsaloli kamar rashin isassun matsi da rashin daidaito, har ma suna buƙatar toshe ramuka akai-akai.Abu na biyu, don magance matsalar rashin isasshen ramuka, ana amfani da hanyar diluting taro tawada a cikin bushewa na gaba.Bushewa yana da buƙatu mafi girma akan bushewa zafin jiki da lokaci.A lokaci guda kuma, ƙarfin raguwar da ake samu a lokacin yin burodi yana da girma, wanda zai iya haifar da ɓarna a cikin sauƙi, da zazzage tawada a bango, da launin rawaya na gefuna, wanda shine abin da ake kira al'amarin rami na zinariya, wanda yake da mahimmanci sosai. don PCB.Ingancin PCB yana da haɗari sosai, don haka ba a karɓar wannan sakamakon gabaɗaya a filayen aikace-aikacen tare da ingancin PCB mafi girma.

Kamar yadda wani m manufacturer qware a cikin fasaha bincike da kuma ci gaban da sarrafa kansa samar da kayan aiki ga PCB plugging, PCB solder mask allo bugu, da PCB allo bugu tafiyar matakai, Xinjinhui ya musamman musamman da kuma ɓullo da wani fasaha matsa lamba toshe inji don magance irin wadannan zafi maki, wanda. ya bambanta da PCB tawada na gargajiya.Na'ura, tsarin haɓakawa mai haɓakawa, nauyin iska na kilogram na iya kaiwa 6-8KG, haɗe tare da tsarin kulle kai da tsarin ɗagawa na ginshiƙai huɗu don tabbatar da daidaito da daidaito.Ramin filogi yana cike da wuka ɗaya, yana kawar da buƙatar maimaita ayyuka da aikin gyaran allo, ingantaccen ingantaccen aiki da haɓaka ƙarfin samarwa A lokaci guda, kowane nau'in asara da sharar gida suna raguwa sosai;saboda amfani da Xinjinhui mai fasaha mai cikakken atomatik pcb ink plugging na'ura zai iya cimma kyakkyawan sakamako, zafin yin burodi a cikin mataki na bushewa na gaba zai iya zama mafi girma, don haka adana lokacin yin burodi ta hanyar 1 ~ 2 hours, yana inganta cikakkiyar fa'ida ga duka. tsari, kuma tanadin makamashi na Xinjinhui ya kai kashi 35%, wanda ke jagorantar masana'antu.Zai iya adana farashin wutar lantarki da yawa don kamfanoni, sauƙaƙe matsin lamba ga masu kera PCB, da kuma samar da tushen ƙimar ƙimar kariyar muhalli.Bada taimako mai ƙarfi.

A takaice, PCB da'irar tawada tawada ramukan da bushewar rami suna da alaƙa a hankali kuma su ne hanyoyin haɗin kai a cikin samar da hukumar PCB.By gabatar da masu kaya na PCB-takamaiman fasaha mai sarrafa kansa da kayan aikin ceton makamashi kamar Xin Jinhui, za mu iya zaɓar kayan aiki tare da ingantaccen makamashi mai ƙarfi, babban matakin fasaha mai sarrafa kansa, rage dogaron ma'aikata, haɓaka shimfidar sararin samaniya na layin samarwa, ƙarfafa samarwa da sarrafa kayan aiki. fadada kasuwa, da dai sauransu. Wannan kora PCB masana'antun cimma high-yi aiki da kuma high quality-samar raga, game da shi rike da rinjaye matsayi a kasuwa.

Lokacin aikawa: Maris 18-2024