Masana'antar hukumar da'ira ta PCB koyaushe tana da kyawawan buƙatu don aiwatar da samarwa.Daga cikin su, jajayen allon da'ira na PCB da ke haifar da buguwar allo na abin rufe fuska abu ne na gama gari wanda ba a so.Ba wai kawai yana shafar kyawun yanayin waje na PCB ba, har ma yana shafar allon kewayawa.Hakanan akwai haɗari masu inganci a cikin wasan kwaikwayon.Wannan labarin – pcb Equipment Network zai kai ku ga samun zurfin fahimtar sanadin da mafita ga ja na PCB hukumar lalacewa ta hanyar solder mask allo bugu a kan PCB kewaye hukumar.

1. Dalilin da ya sa PCB kewaye hukumar solder mask allo bugu sa ja a kan hukumar surface

1. The kauri na solder mask Layer bai kai ga misali ko akwai saura kumfa:

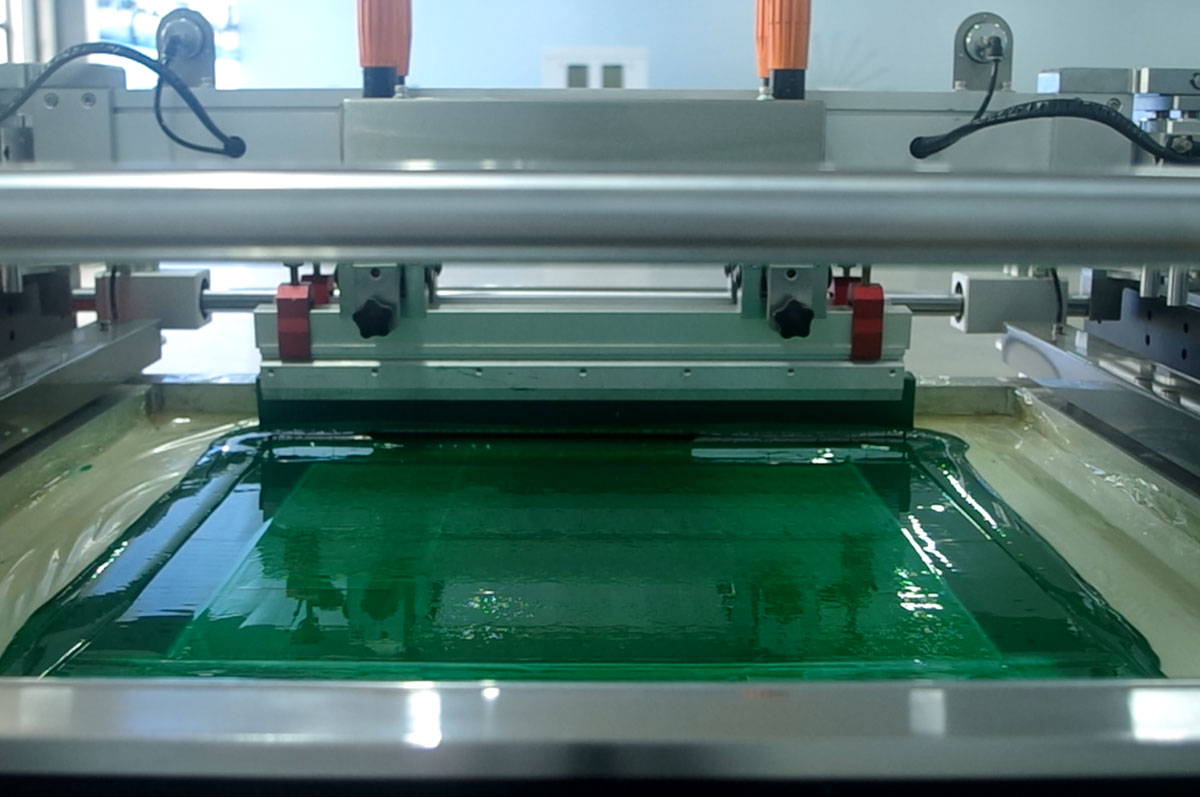

Salon abin rufe fuska yana nufin wani Layer na kariya da aka rufe akan allon kewayawa bayan bugu tare da allon solder na tawada don hana abubuwan da ke faruwa kamar yanayin waje;a lokacin da kauri daga cikin solder mask Layer bai kai ga misali ko akwai saura kumfa, shi wajibi ne don A lokacin wannan mataki, hadawan abu da iskar shaka halayen suna yiwuwa faruwa a lokacin da ci karo da high zafin jiki yanayi, sakamakon ja a kan jirgin saman, haifar da matalauta. PCB inganci.

Idan tawada da kanta da aka yi amfani da ita don buguwar fuskar bangon waya yana da matsaloli masu inganci, kamar tawada da ya ƙare da ƙãra ɗankowar tawada, yana iya haifar da tasirin kariya na abin rufe fuska na solder ɗin ya gaza, ko kuma ba zai iya rufe kewaye gaba ɗaya ba, yana barin gibi da sauran su. ingancin madauki, a ƙarshe yana haifar da abubuwan da ba a so kamar ja a saman allo na iya haifar da haɗarin da ba a sani ba da tasiri akan aikin sa da ingancin sa.

3. Flux da solder tawada abin rufe fuska ba su dace ba:

Rashin ingancin kwalayen da'ira na PCB yana faruwa sau da yawa a cikin daidaitawar matakai masu alaƙa ko kusa.Misali, jujjuyawar juyi da siyar da tawada ba su dace ba ko kuma ba su dace ba, wanda kuma yana iya haifar da rikice-rikice, canjin dukiya, da sauransu, yana haifar da ja ta saman allo.

2. Warware dabarun PCB kewaye hukumar solder abin rufe fuska bugu haddasa ja a kan hukumar surface

1.PCB kewaye hukumar solder abin rufe fuska bugu-pre-samar da ƙayyadaddun ingantawa:

Zaɓin zaɓin tawada abin rufe fuska, ƙirar danko tawada, rayuwar shiryayye ingancin tawada, juyi da sauran abubuwan da suka danganci daidaitattun gudanarwa da ƙa'idodin aiki, ƙirƙirar sigogi da matakai don guje wa haɗarin lahani na PCB da albarkatun ƙasa ke haifarwa.

2.PCB kewaye hukumar solder abin rufe fuska bugu-in-samar da tsari ingantawa:

Na'urar buguwar allo ta PCB tana ci gaba da taƙaitawa da yin gyarawa da ƙirƙira daidaitattun sigogin sigina dangane da buƙatun bugu don tabbatar da ƙimar kimiyya da ma'ana, ta haka ne ke tabbatar da dorewar ingancin samarwa.

3.PCB kewaye hukumar solder mask allo bugu-post-samar ingancin dubawa ingantawa:

Haɓaka matakan aiwatar da ingantattun ingantattun matakai don tabbatar da gano matsalolin akan lokaci don gujewa faɗaɗa asara da rage tasirin tasirin samarwa.

4.PCB kewaye hukumar solder abin rufe fuska bugu-ma'aikata samar horo:

Haɓaka ikon ma'aikata don ganowa, tantancewa, tantancewa da warware matsalolin ingantaccen tsari, haɓaka ƙwarewar ƙwararru da fahimtar ka'idodin matsaloli mara kyau, gudanar da ƙima da horo na yau da kullun, da tsara daidaitattun hanyoyin aiki don ma'aikata su yi aiki yadda ya kamata kuma daidai, da amsawa. don magance matsalolin daban-daban a kan lokaci.yanayin gaggawa.

3. PCB kewaye hukumar solder mask allo bugu sa hukumar surface zama ja.Abin da za a yi a taƙaice

Matsalar PCB kewaye hukumar solder abin rufe fuska bugu hukumar redness ne na kowa matsala a samar da tsari, amma ba mai rikitarwa matsala.Sau da yawa ƙananan ƙananan ne kawai kuma a farkon matakin, kuma yana da sauƙi don faruwa a cikin masana'antun da ba su da kwarewa da kuma daidaitacce.Don warware wannan matsala, da mayar da hankali bukatar da za a kafa Professional da daidaitattun hanyoyin aiki, zabar dace PCB kewaye hukumar solder allo bugu inji kayan aiki da kuma kwararrun masu aiki don kauce wa faruwa na irin wannan low-matakin kurakurai, wanda zai shafi kamfanin ta inganci da kuma m. amfani.

Lokacin aikawa: Maris 12-2024